so that's how it started:

...So I got myself a Perazzi MX8 type 4 (eventually IDed as Mirage), as per a friend (excellent bunker shooter, shooting encyclopedia)

from the club, who made a beautiful stock for it.

I know next to nothing about Perazzi's guns, I really trust what he says, but what puzzles me is the fact that there is no model # stamped anywhere on the gun. Receiver on both sides is empty and smooth...

80363 & AZ indicate 1990 year, numbers match -receiver, barrels, trigger group, & forend; gun is tight and pleasantly lively when swinging, quite a change from my XT 'cannon'

Barrels 30", top is fixed full ~17.25, bottom changeable chokes, not much wear on the hammers.

My friend says that most likely it was special order where client didn't wish model stamping on the gun..

After several rounds lower barrel f.pin broke, replaced with new pins , removed the web on the hammer, cleaned the pin orifices; started getting light hits on top barrel, found that the new pin (striking part,) is shorter then then the old one is shorter by .5mm, put the old back in, less misfires but still some nevertheless.

-removed cocking bar (was moving freely ) and clean it, removed ejector trip rods (were sticky) & cleaned them and the channels, still light hits, removed them, still light hits, appeared less numerous.

-borrowed trigger group from a friend, four rounds - no problem.

-firing pins return springs arrived, decided to strip the receiver to give it a good cleaning, had a quite a problem to remove the top lever, lot of dirt and some burs removed with 600 stone, lubed lightly with lithium grease (that I used forever on my guns without adverse effects, but would like to hear you opinion on this type).

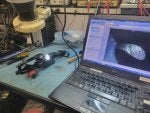

Noticed that the the hole where the f.pin return spring dwells has ribbed-like pattern, imprinted (I guess) by the gunk accumulated there, cleaning neglect, one may guess, for many years. That part of the of the hole not leally visible without top lever off. Proceeded with cleaning with a brush (pic), still looked rough. Took it under microscope (pics) as you can see it's not smooth.

Replaced the f.pins return springs and re-assembled, put a new top lever return spring for good measure (was a bit deformed).

And now if I don't have light hits no more, I would know if it was cleaning the far end of the hole or new f.p. return spring

If the problem still persist I would be at loss...

![Image]()

...So I got myself a Perazzi MX8 type 4 (eventually IDed as Mirage), as per a friend (excellent bunker shooter, shooting encyclopedia)

from the club, who made a beautiful stock for it.

I know next to nothing about Perazzi's guns, I really trust what he says, but what puzzles me is the fact that there is no model # stamped anywhere on the gun. Receiver on both sides is empty and smooth...

80363 & AZ indicate 1990 year, numbers match -receiver, barrels, trigger group, & forend; gun is tight and pleasantly lively when swinging, quite a change from my XT 'cannon'

Barrels 30", top is fixed full ~17.25, bottom changeable chokes, not much wear on the hammers.

My friend says that most likely it was special order where client didn't wish model stamping on the gun..

After several rounds lower barrel f.pin broke, replaced with new pins , removed the web on the hammer, cleaned the pin orifices; started getting light hits on top barrel, found that the new pin (striking part,) is shorter then then the old one is shorter by .5mm, put the old back in, less misfires but still some nevertheless.

-removed cocking bar (was moving freely ) and clean it, removed ejector trip rods (were sticky) & cleaned them and the channels, still light hits, removed them, still light hits, appeared less numerous.

-borrowed trigger group from a friend, four rounds - no problem.

-firing pins return springs arrived, decided to strip the receiver to give it a good cleaning, had a quite a problem to remove the top lever, lot of dirt and some burs removed with 600 stone, lubed lightly with lithium grease (that I used forever on my guns without adverse effects, but would like to hear you opinion on this type).

Noticed that the the hole where the f.pin return spring dwells has ribbed-like pattern, imprinted (I guess) by the gunk accumulated there, cleaning neglect, one may guess, for many years. That part of the of the hole not leally visible without top lever off. Proceeded with cleaning with a brush (pic), still looked rough. Took it under microscope (pics) as you can see it's not smooth.

Replaced the f.pins return springs and re-assembled, put a new top lever return spring for good measure (was a bit deformed).

And now if I don't have light hits no more, I would know if it was cleaning the far end of the hole or new f.p. return spring

If the problem still persist I would be at loss...