I would like to attempt 3D printing a repro of the now-elusive TS Shell Catcher for the Remington 1100 & 11-87. I've been wanting one for a while and I've seen a few recent mentions of it on this forum, so I figured it's worth some time.

Would anyone out there with the plastic version be willing to sit down with a micrometer and send me as many detailed measurements as they can - including some 360 pics?

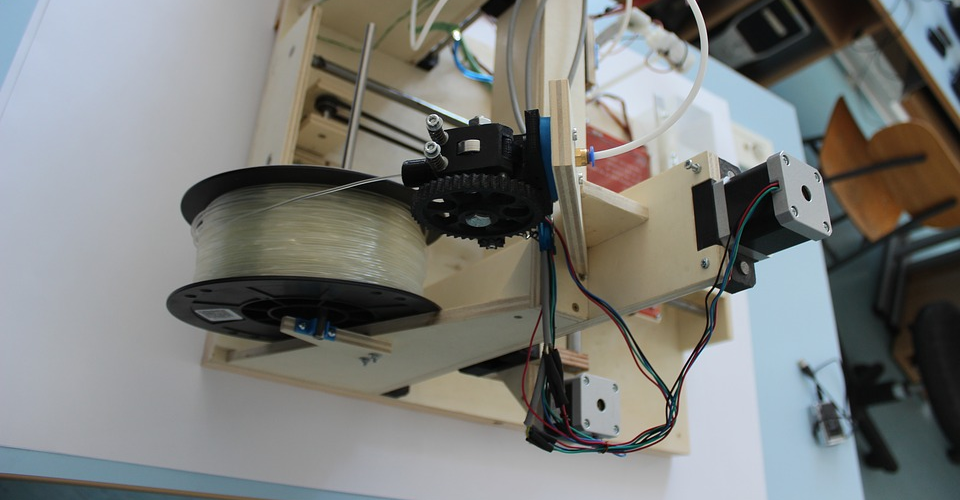

I'm looking to hire a CAD designer to mock up the model and then I'll attempt to print it myself. I cannot promise success, but if I find it, I'd be happy to send a couple prints to whomever was able to help!

Thanks all!

Would anyone out there with the plastic version be willing to sit down with a micrometer and send me as many detailed measurements as they can - including some 360 pics?

I'm looking to hire a CAD designer to mock up the model and then I'll attempt to print it myself. I cannot promise success, but if I find it, I'd be happy to send a couple prints to whomever was able to help!

Thanks all!